The Indian sugar industry has traditionally relied on two major processes, double sulphitation and the raw–refined process, to convert sugarcane juice into plantation white sugar and raw/refined sugar. Among these, the double sulphitation method is considered less environmentally friendly. To address this challenge, under the leadership of the Director, Prof. Seema Paroha, a research team led by Mahendra Kumar Yadav, Assistant Professor (Sugar Technology), has developed and successfully tested an eco-friendly sugar production process based on natural clarificants. This research work was carried out under an MoU signed between the National Sugar Institute (NSI), Kanpur and Ms RAITAN Pvt. Ltd.

In this innovative process, a tannin-based natural coagulant has been used in place of sulphur-based clarification. The tannin-based natural coagulant is obtained from the Quebracho tree, found in Argentina, and was provided to NSI by Ms RAITAN Pvt. Ltd. for research purposes. Similar tannin extracts can also be obtained from various trees available in India, such as babul, jamun, arjun, baheda, mango bark, neem bark, eucalyptus, harad, khair, etc.,

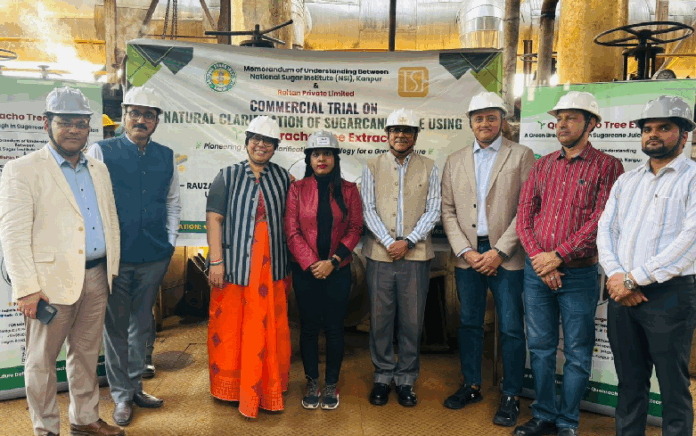

The initial research was conducted in the NSI research laboratory and later validated in the laboratory of a commercial sugar mill. Based on the promising results, a full-scale commercial trial was conducted at Balrampur Chini Mills Ltd., Unit – Rojagaon, Ayodhya. The objective was to evaluate the feasibility of adopting plant-based extracts as a sustainable alternative to conventional sulphur-dependent clarification, thereby eliminating sulphitation and promoting the production of organic sugar.

This commercial trial was carried out smoothly and without any operational difficulties between 16.11.2025 and 18.11.2025, in the presence of the Director, NSI, Kanpur. During the trial, Anurag Verma (Technical Assistant &) and Shalini Verma (Research Scholar) provided essential analytical support. The results clearly demonstrated that the natural extract-based process significantly reduced the consumption of lime (milk of lime), eliminated the need for flocculants, and produced sugar of superior quality compared to the conventional method. Notably, the colour of the final sugar improved by approximately 70%, marking a major advancement in product quality.

These findings reaffirm the potential for all double-sulphitation units to transition toward this environmentally responsible technology, aligning with national sustainable development goals and global trends in green industrial practices. This accomplishment stands as a major milestone for the Indian sugar industry and presents a promising pathway toward clean and organic sugar production.

Green Breakthrough in Sugar cane Juice Clarification

-Eliminating Conventional sulphur-dependent clarification

-pH increased naturally

-Purity rise by 2-3 units

-Turbidity Drastically reduced

-Milk of Lime consumption reduces

-Colour of the final sugar improved by approximately 70%,

-Higher Purity & Better efficiency

-100% Eco friendly & biodegradable

-Low Sludge formation

-Reduction in COD levels will reduce the cost of effluent treatments